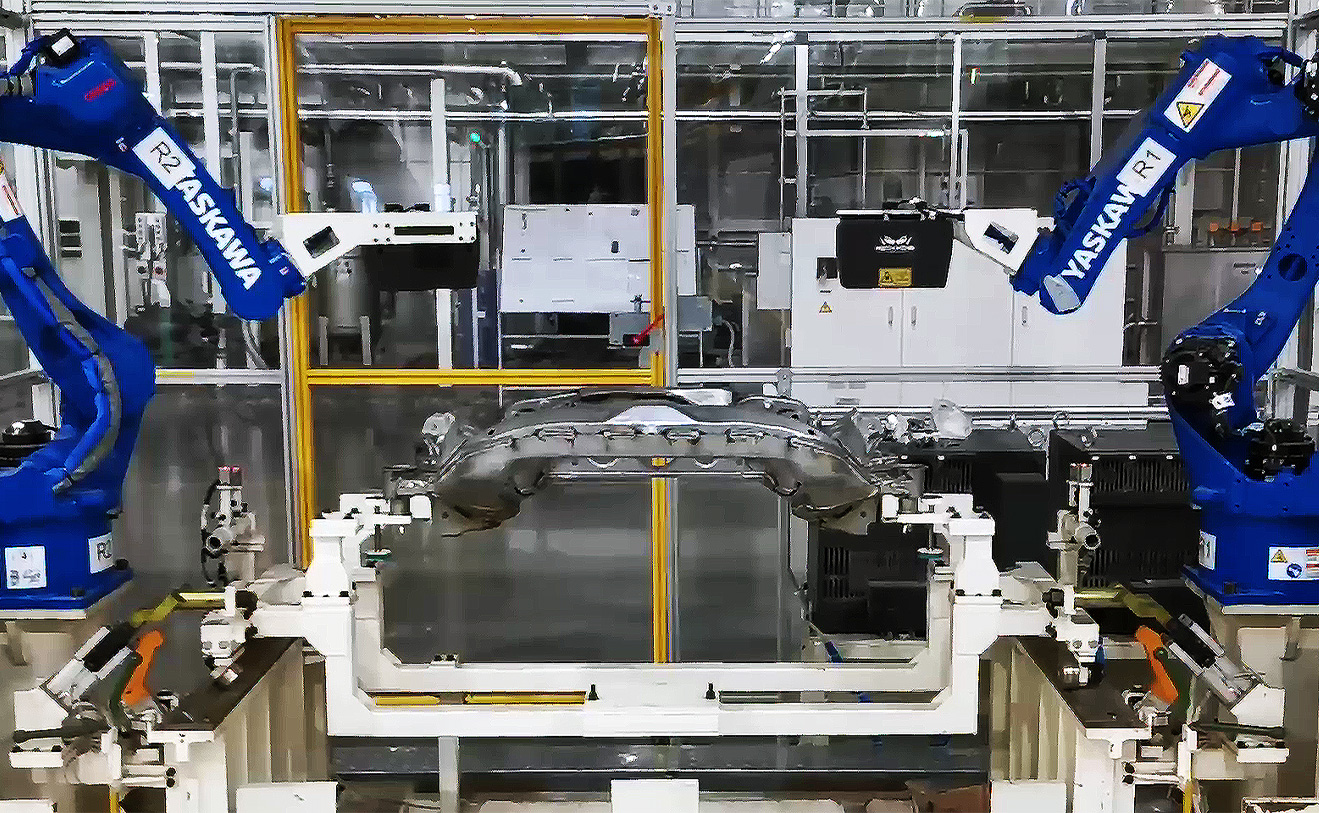

Automobile sub -frame 3D positioning guidance & dimensional measurement

-

Project Description

- The project service target is a large international car hosting plant. The factory welded workshop needs to measure the key parameters of each assembly characteristics of the large workpieces.

- The measurement content mainly includes a differential tolerance of various types of pores, position, plane, and coaxiality to avoid the final assembly effect due to the excessive error of a single component.

- The accuracy requires ± 0.2mm, and the overall testing joint requires 130s.

-

Characteristic

- Used with micron -level accuracy 3D camera, to generate high -quality point cloud data on the sub -frame feature hole with strong reflection on the surface;

- Adopting self -developed intelligent measurement algorithms can measure ordinary round holes, thread holes, threads, lumbar holes and other characteristic types, and high measurement accuracy;

- Support multi -camera multi -robotic work, flexibly cope with the characteristic holes of different positions, and quickly complete the measurement tasks of various large -scale workpieces;

- The overall system accuracy is high, and the measurement accuracy ≤0.2 mm;

- The measurement data can be organized, and the historical records and output measurement reports are supported to support custom screening, which facilitates data traceability and analysis.

Characteristic

Characteristic