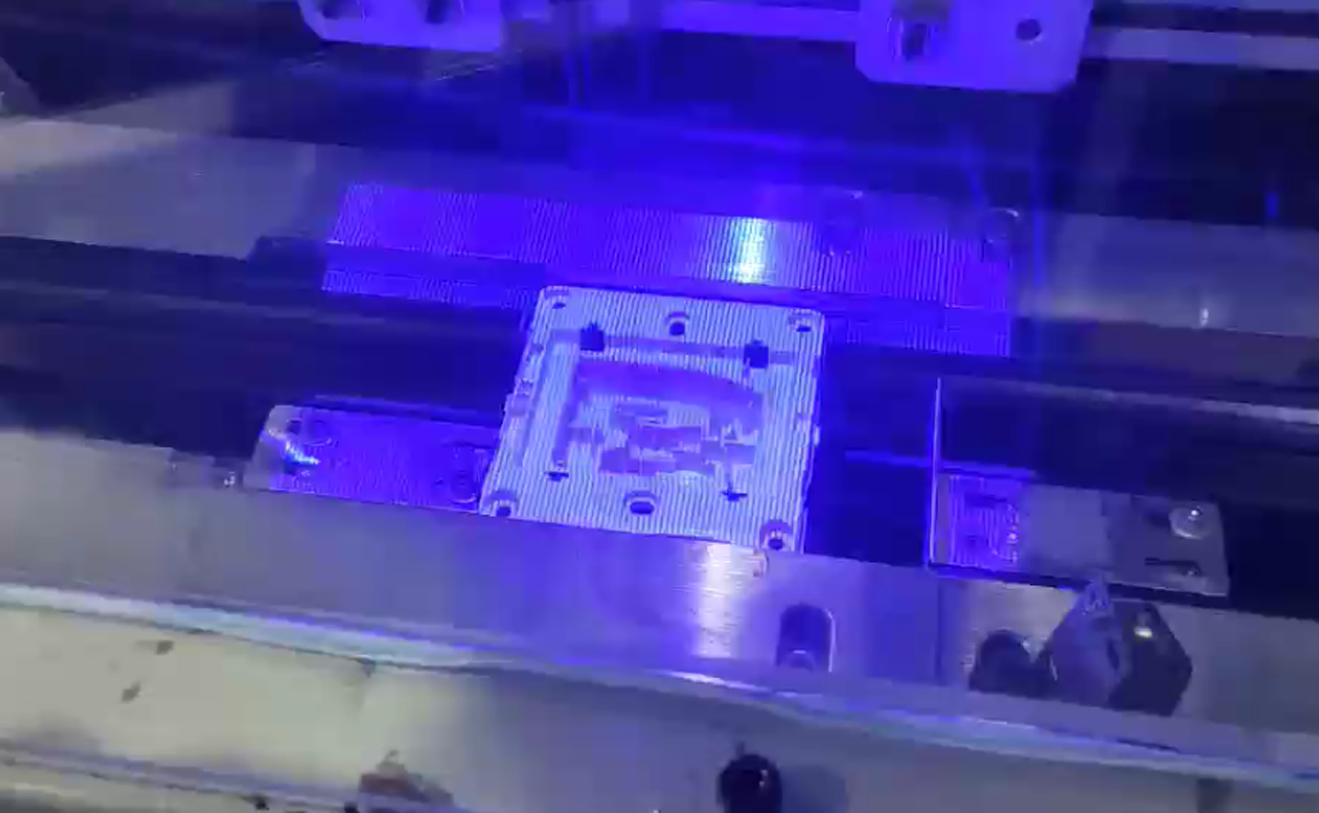

Bull socket 3D dimensional measurement

-

Project Description

- The service object of the project is a factory of Bull Socket, whose switch injection parts are made of copper on both sides of the bar. Whether the height and size of the bar meet the standard and whether there are injection defects will affect the safety of the switch;

- The workpiece size detection accuracy is required to reach 0.1mm;

- There are many kinds of workpieces, which need to be compatible with the dimensional measurement of various products;

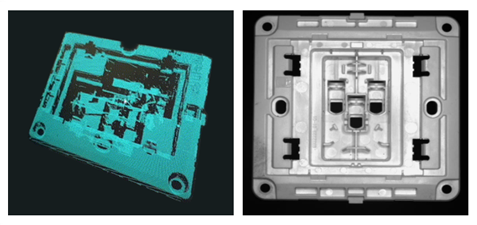

- The workpiece measurement holes are arranged in different planes, requiring 3D system imaging.

-

Characteristic

- It is used with high-precision binocular laser galvanometer 3D camera, and adopts high-speed point cloud acquisition technology to avoid production line jitter interference and meet the requirement of workpiece size ±0.1mm detection accuracy.

- Self-developed algorithms such as cluster analysis and noise reduction, 3D point cloud to 2D graph processing are adopted to greatly improve the matching accuracy and reduce the algorithm processing time, and the single detection time is less than 3S.

- Supports product switching management and data statistics, which can easily and efficiently switch product types and deliver detection function parameters accordingly.

Characteristic

Characteristic